BLOG

How Does a Pressure Relief Valve Work?

- 10 Nov 2025

The Short Answer: A pressure relief valve is a safety device that automatically opens when internal pressure exceeds a set pressure limit. This safety mechanism works by using a spring-loaded mechanism that releases excess pressure to prevent equipment failure or damage.

In industrial settings, managing pressure safely is fundamental to preventing accidents and equipment damage. Pressure relief valves and safety relief valves serve as mechanical safeguards in applications ranging from steam boilers and chemical processing to pneumatic systems and pressure vessels. These safety devices operate continuously and automatically, providing round-the-clock protection for machinery, personnel, and facilities.

This article explains how pressure relief valves function, explores their main components, and details their applications across various industries. You’ll understand the mechanics behind these pressure safety valves, their regular maintenance requirements, and how to select the right type for specific uses.

Core Operating Principles

Three Main Components

A pressure relief valve is a safety feature that operates through the coordinated action of three fundamental components working together. The safety valve element consists of a spring-loaded relief valve that controls the flow of fluid. The sensing element, which may be a diaphragm or piston depending on the application, monitors internal pressure. The reference force element, typically a spring-loaded mechanism, provides the counterpressure that keeps the valve closed until the set pressure point is reached.

Basic Working Mechanism

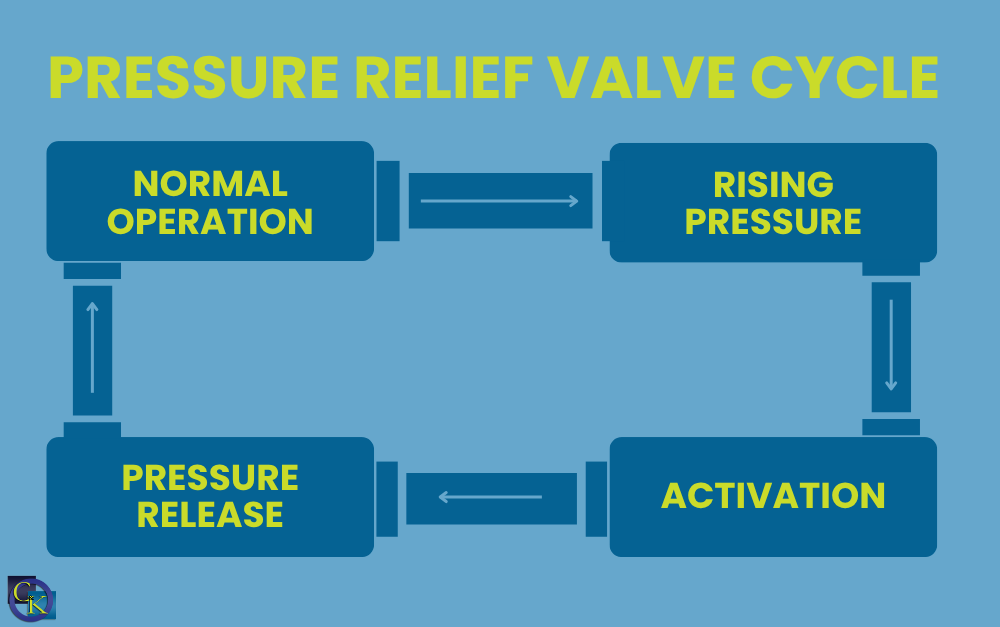

In normal operation, the pressure relief valve maintains a closed position as the spring exerts downward force on the valve disk, forming a seal at the valve seat. The system constantly monitors upstream pressure through the valve disc. When pressure reaches the predetermined threshold, it overcomes the spring force, causing the valve to lift from its seat. This creates an opening that allows excess pressure to discharge through the outlet port, preventing pressure buildup.

Pressure Monitoring and Response

The valve’s set pressure determines when it activates, typically calibrated through adjusting spring tension. Once pressure exceeds this point, the safety relief valve responds automatically, opening wider as pressure increases to allow greater flow and gradually closing as pressure decreases. The valve reseats when upstream pressure drops several PSI below the set point, returning to its normal closed position. This self-regulating safety mechanism provides reliable pressure control without manual intervention.

For consistent performance, the sensing element must match the application. Diaphragm designs work best for low-pressure and high-accuracy needs, while piston-style sensors handle higher pressures but with slightly slower response times due to seal friction. The spring must also be appropriately sized and rated for the expected pressure level and operating conditions.

Types of Pressure Relief Valves

Spring-Loaded Relief Valves

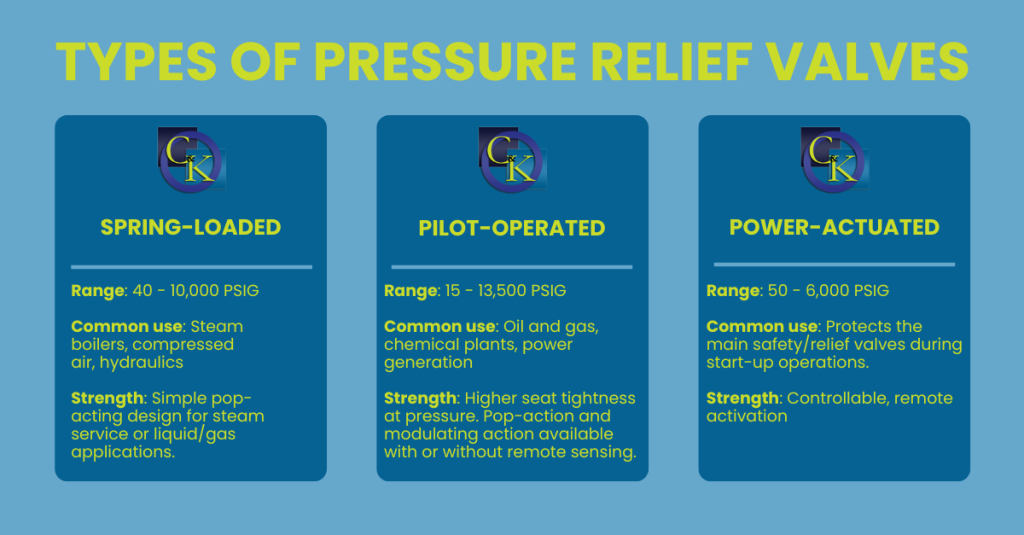

Spring-loaded relief valves are the most traditional and widely used pressure safety valves across industrial systems. In this design, a spring applies a calibrated force to keep the valve seat closed under normal operating conditions. When system pressure rises beyond the spring’s set threshold, the pressure force overcomes the spring tension, lifting the valve disc and releasing excess pressure through the discharge port.

These valves are known for their simplicity, reliability, and quick response time. They provide dependable protection for systems ranging from 40 to 10,000 PSI, making them ideal for steam boilers, air compressors, and hydraulic lines. The key components—a spring, valve disc, and seat—work together to ensure consistent reseating once pressure returns to safe levels. Because of their straightforward design, spring-loaded valves remain a cost-effective and durable choice for general overpressure protection. The trim of spring-loaded relief valves is often specialized for operation on steam, gas, or liquid media, with specialized trim for cryogenic applications. Some manufacturers offer a single “Dual Media” (different than dual-certified) trim that can be used for both liquid and gas applications simultaneously. Dual Media trim is optimal for mix-phased flow applications like flashing or fire-case scenarios. Use of the Dual Media valve can have the added benefit, due to its versatility, of reducing the number of spare valves required to support a process.

Pilot-Operated Relief Valves

Pilot-operated relief valves use a two-valve system to provide more precise pressure control, especially in high-pressure or high-flow applications. Instead of a spring alone, these systems use a smaller pilot valve to sense pressure changes and control the main valve’s opening. When the set pressure is exceeded, the pilot valve opens first, venting pressure from the dome chamber and allowing the main valve to lift fully open.

Since the dome area of the main valve is larger than the seat area, PORVs seal tighter than spring-loaded relief valves when system pressure begins to approach the set point. PORVs have the additional advantage of being able to modulate pressure relief, minimizing media loss during an overpressure condition.

If the location of the relief valve in the system or the inlet piping configuration causes a loss of pressure (inlet line loss) > 3%, pilot valves should be used because they are capable of remote sensing of inlet pressure for proper operation.

There are a several situations where a pilot valve, with all of their benefits, can be a more cost effective solution than a simple spring-loaded relief valve: If the relief valve has a exhaust header shared with other valves (a potential back pressure condition), pilot valves may be more economical than a spring-loaded relief valve that would typically require costly bellows to protect against back pressure conditions. Some valve manufacturers offer pilot valves that can slot into an API 526 footprint without piping modifications (including conditions where the pilot valve is integrally sensed). As the size of the main valve increases (typically around an orifice size of M or N and certainly around size P and larger), pilot-operated relief valves become the more economical solution due to the smaller-sized spring and reduced overall valve body dimensions.

Depending on the manufacturer, pilot valves may be able to be configured with a single “Triple Media” trim designed to operate on steam, liquid, and gas media.

Power-Actuated Relief Valves

Power-actuated relief valves integrate electrical, pneumatic, or hydraulic actuators to open or modulate the valve position actively. Unlike spring or pilot-operated designs, which rely solely on pressure changes to function, these valves use an external power source to trigger or assist the opening mechanism. When system pressure nears the set point, sensors signal the actuator to open the valve, providing rapid and controlled pressure relief.

These valves are ideal for automated systems requiring precise timing or remote operation. They allow operators to manage relief functions electronically, making them well-suited for modern industrial plants, chemical processing systems, and critical safety loops. Power-actuated valves can also serve dual functions—acting as both safety and process control valves—enabling integration with advanced monitoring systems. Their design ensures consistent, responsive operation even in complex or high-risk environments.

Material and Design Considerations

Common Construction Materials

The construction of pressure relief valves requires careful material selection to match operating conditions. Stainless steel (grades 303 and 316) offers excellent strength and corrosion resistance for high-temperature or corrosive fluids. Monel and Hastelloy alloys provide superior protection in marine and chemical processing environments, where resistance to acids and oxidation is critical. Brass remains a cost-effective option for general service, while aluminum offers a lightweight alternative for low-pressure systems.

Brass serves as a common choice for many pressure vessels, offering good durability at a reasonable cost. Pressure relief valves can be metal-seated, soft-seated, or soft-seated with a metal backup seat, depending on the application and required sealing performance. For sealing components, manufacturers commonly use Buna-N rubber for general service, while more demanding environments may require advanced elastomers such as fluorocarbon, EPDM, silicone, or Chemraz® (FFKM) for superior chemical and temperature resistance.

Selection Factors

Flow requirements play a major role in sizing decisions. The pressure relief valve must accommodate the maxim expected flow rate of one or more media while maintaining consistent performance across varying conditions. Orifice sizes and configurations need careful consideration – undersized valves don’t have sufficient capacity to relieve excess pressure and oversized valves “chatter” during relief conditions which damages the valve trim.

Temperature considerations affect both material selection and overall valve performance. The chosen materials must maintain their mechanical properties across the full operating temperature range. This particularly applies to seal materials, which can degrade or lose effectiveness if used outside their temperature specifications.

Safety Standards

Industrial safety relief valves must meet strict safety codes and certifications. The American Society of Mechanical Engineers (ASME) provides detailed standards for pressure relief devices used in pressure vessels and boilers. The American Society of Mechanical Engineers (ASME) governs these standards through two primary sections:

- ASME Section I – Fired Pressure Vessels such as steam drums, superheaters, reheaters, and economizers.

- ASME Section VIII – Unfired Pressure Vessels used in off-boiler applications.

The National Board of Boiler & Pressure Vessel Inspectors (NB) serves as the certifying agency for relief valve repair and assembly. Chalmers & Kubeck maintains NB Authorized Relief Valve Repair (VR) certification, including “V” (Vessel), “UV” (Unfired Vessel), and “TO” (Test Only) designations.

Testing and maintenance schedules may also be dictated by the facility’s insurance providers or regulatory authorities to ensure ongoing compliance. Proper installation practices—such as secure mounting, accessible placement for maintenance, and safe discharge routing—are critical for reliable operation. Regular inspection, testing, and documentation per ASME and NB guidelines help maintain system integrity and ensure continued protection in demanding industrial environments.

Chalmers & Kubeck Knows Valves

Pressure relief valves play an indispensable role as a safety mechanism protecting industrial systems from dangerous overpressure conditions. These safety devices combine three main components (the valve seat, sensing element, and reference force element) working together to automatically release excess pressure when needed. Regular maintenance of these pressure safety valves helps prevent equipment failure and keeps operations running safely.

For optimal performance, pressure relief valves require professional servicing to verify spring-loaded mechanisms, seal integrity, and set pressure accuracy. Chalmers & Kubeck provides expert maintenance to keep relief systems operating safely and reliably across the East Coast.

Our technicians are factory-trained, certified, and recertified annually, ensuring every service meets the highest industry standards. Each of our service centers is audited annually by Baker Hughes to maintain stringent quality and compliance requirements. In addition to being a certified Valve Repair (“VR”) Shop, C&K is also a certified relief valve assembler with an extensive list of National Board certifications.

We offer 24/7 emergency service, precision repairs, and comprehensive valve testing across all major valve types and industrial applications. Contact us today to schedule professional valve maintenance and safeguard your critical systems with C&K’s proven expertise and certification-backed reliability.